Reduced Scale Build-up Leads to Lower Maintenance Costs

- Understanding Scale Formation: Scale is primarily composed of calcium and magnesium minerals found in hard water. These minerals precipitate out of the water when it is heated, leaving behind a hard, crusty deposit. This scale build-up is not just unsightly; it can have severe implications for industrial machinery and piping systems.

- Impact on Piping Systems and Machinery: In factories, scale can accumulate in pipes, valves, and on the surfaces of boilers, heat exchangers, and other water-handling equipment. This accumulation can lead to blockages, reducing the flow rate of water and causing stress on pumps and other components. In heating systems, even a thin layer of scale acts as an insulator, making heat transfer less efficient and forcing the systems to work harder, which in turn consumes more energy and increases operating costs.

- Maintenance and Downtime Costs: To address the problems caused by scale build-up, factories often have to schedule regular maintenance. This involves not only the direct costs of cleaning and possibly repairing the affected equipment but also the indirect costs associated with downtime. Production may need to be halted during maintenance, leading to a potential loss of revenue and productivity.

- Extending Equipment Lifespan: Regular exposure to scale can significantly shorten the lifespan of industrial equipment. By preventing scale formation through water treatment, factories can extend the service life of their equipment. This means less frequent replacements, saving substantial amounts of money in the long term.

- Improvement in Efficiency: Scale-free systems operate more efficiently. For instance, in heating systems, improved heat transfer efficiency translates to lower fuel consumption, reducing energy bills. In cooling systems, better heat transfer efficiency means less energy is required to maintain optimal temperatures, again leading to cost savings.

Enhanced Efficiency of Heating Systems

The efficiency of heating systems in industrial settings is crucial, not only for the operational processes but also for energy consumption and cost control. Treating hard water plays a significant role in enhancing the efficiency of these systems. Here’s a closer look at how water treatment contributes to more efficient heating systems:

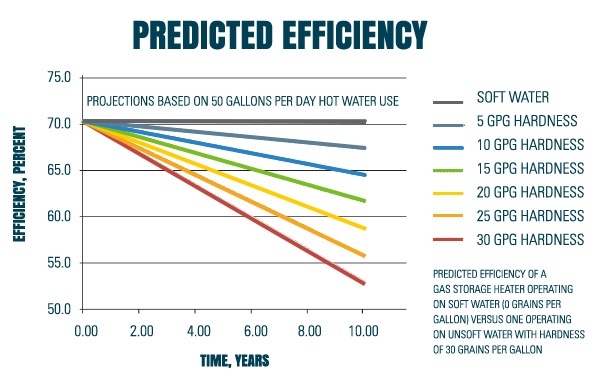

- Preventing Scale in Heating Equipment: When hard water is heated, it tends to leave behind scale – a deposit of calcium and magnesium. This scale can form on the interior surfaces of boilers, pipes, and heat exchangers. Even a small amount of scale can significantly reduce the efficiency of heating equipment. The insulating effect of scale means more energy is required to achieve the same heating level, leading to increased energy consumption and higher utility bills.

- Improved Heat Transfer: The primary function of boilers and heat exchangers is to transfer heat efficiently. Scale formation acts as an insulating layer, hindering this heat transfer. By using softened water, the heat transfer process becomes more efficient as there is no scale to impede it. This efficiency translates to a reduction in energy consumption and, therefore, lower operational costs.

- Reduced Energy Consumption: With improved heat transfer efficiency, heating systems require less energy to maintain desired temperatures. This reduction in energy demand leads to lower energy costs. For factories where heating is a significant part of the process, these savings can be substantial over time.

- Lower Maintenance and Repair Costs: Heating systems affected by scale need more frequent maintenance, which includes descaling and cleaning. In some cases, parts affected by scale might need replacement. Soft water reduces the frequency of these maintenance requirements, leading to lower ongoing costs. Additionally, with less wear and tear from scale, the likelihood of breakdowns and costly repairs is significantly reduced.

- Extended Lifespan of Heating Equipment: Consistent use of hard water in heating systems accelerates the aging process of the equipment. By eliminating the cause of scale formation, softened water can extend the lifespan of these systems. This means factories can defer the capital expenditure of replacing boilers and other heating equipment.

- Environmental Impact and Sustainability: More efficient heating systems mean less fuel consumption for the same output, which has a positive impact on the factory's carbon footprint. Using less energy contributes to a factory’s sustainability goals and can be an essential part of a broader environmental responsibility strategy.

Extended Lifespan of Industrial Machinery

The longevity and reliability of industrial machinery are pivotal for the sustainable operation of any factory. Hard water, with its high mineral content, can significantly shorten the lifespan of this machinery. Treating the water hardness used in these industrial applications can thus have a profound impact on extending the machinery's lifespan. Here’s a detailed exploration of how this works:- Understanding the Damaging Effects of Hard Water: Hard water contains high levels of minerals like calcium and magnesium, which can precipitate and form hard deposits (scale) on machinery. These deposits are not just a surface issue; they can infiltrate and damage critical components, leading to increased wear and tear. The abrasive nature of these minerals can also lead to corrosion and erosion of metal parts, further reducing the lifespan of the machinery.

- Protection Against Scale Accumulation: Scale build-up is a major concern in equipment that involves heat exchange or water movement, such as boilers, cooling towers, and pumps. Over time, scale can clog pipes, reduce flow rates, and impair the functioning of machinery. By using softened water, the formation of scale is greatly reduced, thereby protecting the internal components of the machinery from damage and ensuring smoother operation.

- Enhanced Operational Efficiency: Machinery operating with softened water runs more efficiently. When equipment is not battling scale build-up or corrosion, it can operate at its intended performance levels. This not only ensures optimum productivity but also reduces the strain on the machinery, which in turn prolongs its operational lifespan.

- Reduced Corrosion and Wear: Soft water, being free from the harsh minerals found in hard water, is gentler on machinery. This means less corrosion and wear on the internal components, which are often expensive to repair or replace. Regular exposure to hard water can accelerate the deterioration of these components, so soft water can substantially extend the time between repairs.

- Cost Savings in Maintenance and Replacement: The direct cost savings from using treated water come in the form of reduced maintenance requirements and a delay in the need for replacement of machinery. Less scale and mineral-induced damage mean fewer breakdowns and a lower frequency of maintenance. Moreover, extending the lifespan of machinery delays the significant capital expenditure associated with purchasing new equipment.

- Improvement in Quality of Output: The quality of water used in manufacturing processes can affect the quality of the final product. Treating hard water effectively and efficiently ensures that machinery operates at its best, which can lead to improvements in product quality and consistency. This aspect is especially crucial in industries where water is a direct component of the product, such as in beverages or pharmaceuticals.

- Environmental Considerations: Treatment for water hardness can contribute to environmental sustainability. Machinery that operates more efficiently and lasts longer consumes less energy and resources over its lifetime. This reduced resource consumption aligns with environmentally friendly practices and sustainability goals of many modern factories.

Conclusion

In addressing the challenges of hard water in industrial settings, the benefits of water treatment are multifaceted and impactful. Reduced scale build-up from treating hard water leads to lower maintenance costs, as scale is a major cause of equipment inefficiency and damage. By preventing these hard mineral deposits, factories can save substantially on repairs and downtime. Additionally, softened/conditioned water enhances the efficiency of heating systems. Scale acts as an insulator, reducing heat transfer efficiency and increasing energy costs. Removing this barrier ensures optimal operation and energy savings. Moreover, the lifespan of industrial machinery is significantly extended with treated water. Hard water can accelerate machinery wear and tear, leading to frequent replacements and repairs. By mitigating these effects, factories can enjoy prolonged equipment life and reduced capital expenditures.

For industries looking to tackle the challenges of hard water and reap the benefits of water treatment, HydroFLOW provides a compelling solution. By choosing HydroFLOW, factories can enhance their operational efficiency, reduce maintenance costs, and extend the life of their equipment, all while contributing to environmental sustainability. To explore the full range of products and understand how HydroFLOW can revolutionize your water treatment process, visit HydroFLOW Canada.